Steel Shot And Grit

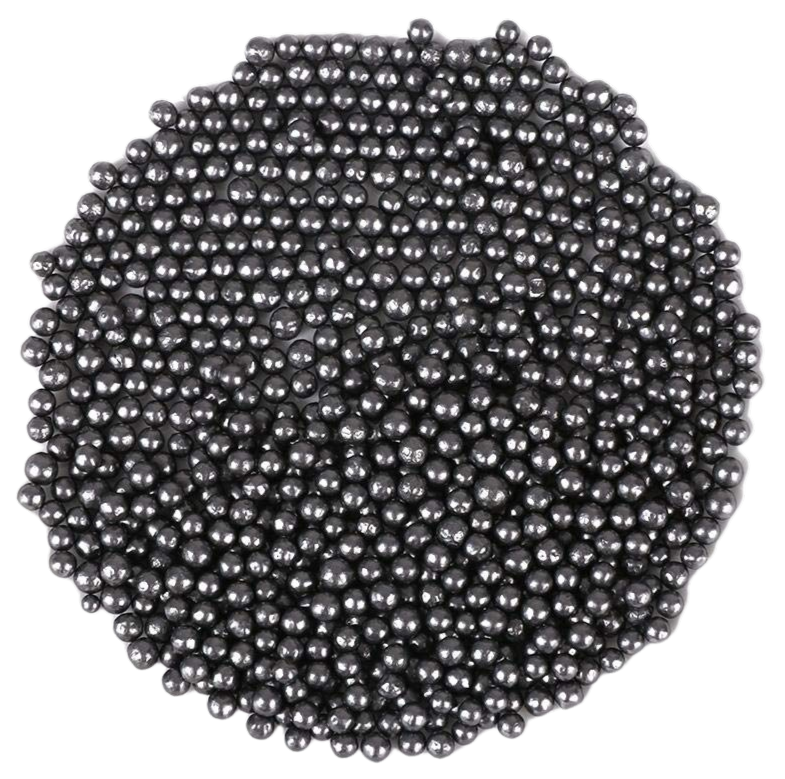

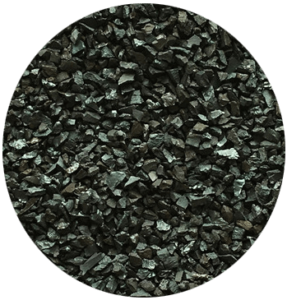

Orient shot are produced under a controlled manufacturing process to achieve a product of uniform hardness, density and microstructure, coupled with good toughness for durability. These factors result in abrasives of sufficient hardness to perform its cleaning function as well as an extended life. Orient abrasives come in two forms: shot, grit.

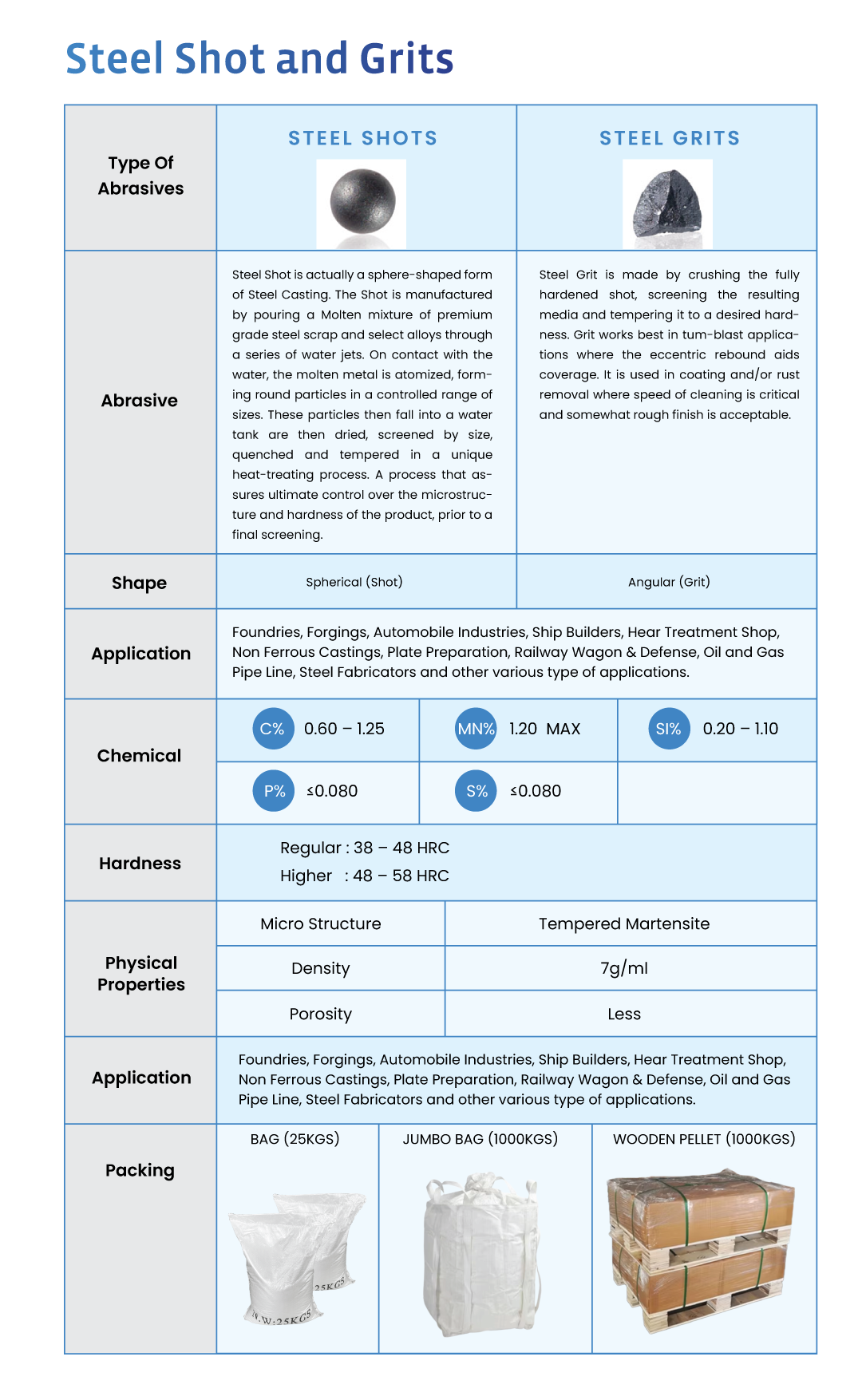

Steel shot is actually a sphere-shaped form of steel casting. The shot is manufactured by pouring a molten mixture of premium grade steel scrap and select alloys through a series of water jets. On contact with the water, the molten metal is atomized, forming round particles in a controlled range of sizes. These particles then fall into a water tank, are then dried, screened by size, quenched and tempered in a unique heat-treating process. A process that assures ultimate control over the microstructure and hardness of the product, prior to a final screening.

Steel Grit is made by crushing the fully hardened shot, screening the resulting media and tempering it to a desired hardness. Grit works best in tumblast applications where the eccentric rebound aids coverage. It is used in conting and/or rust removal where speed of cleaning is critical and somewhat rough finish is acceptable.

FEATURES OF OUR STEEL SHOTS

| Uniform Hardness | Makes cleaning operations fast and effective. |

| Cleaning | Surface is cleaned uniformly. Each and every particle of our shots are reaching into the very integrated parts of the Blasted Components during blasting operation and removes the sand. |

| Resilience | Which confirms a longer life. |

| Life | Due to extreme toughness and controlled hardness, our Steel Shots can be used more and more time and cut down the cost in Peening and Cleaning operation and also save the machine part. |

APPLICATIONS

Foundries, Forgings, Automobile Industries, Ship Builders, Hear Treatment Shop, Non Ferrous Castings, Plate Preparation, Railway Wagon & Defense, Oil and Gas Pipe Line, Steel Fabricators and other various type of applications

SPECIFICATIONS

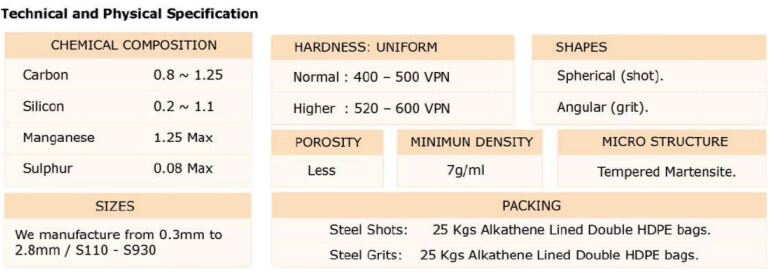

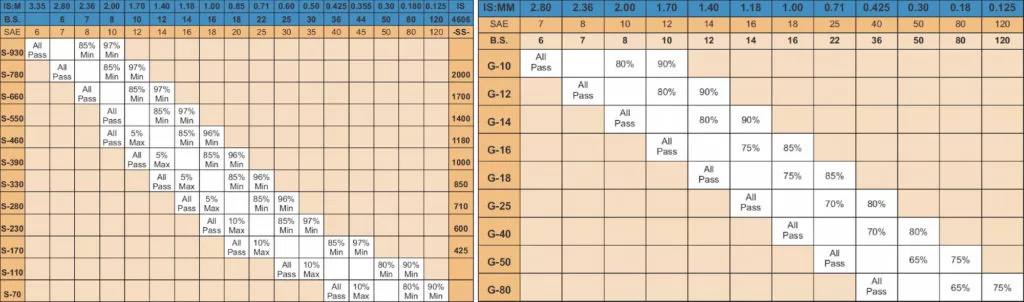

Specification of Shot Screening